Media OutReach

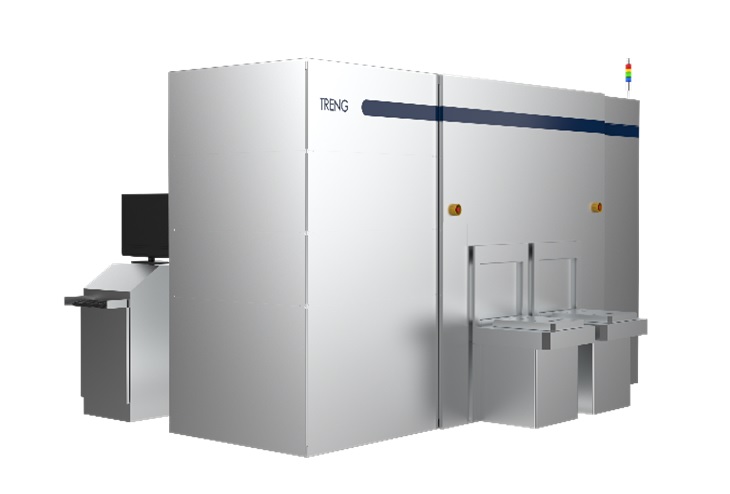

Launch of TRENG-PLP Coater

Panel Level Coater for Advanced Semiconductor Packaging

HONG KONG SAR – Media OutReach Newswire – 9 December 2024 – Toray Engineering Co.,Ltd has developed the “TRENG-PLP Coater”, a high-accuracy coating device for panel level packaging (PLP is an advanced semiconductor packaging technology) for which there is growing demand particularly from AI servers and data centers. Sales of the Coater will commence in December 2024.

The Coater enables 2.5D packaging—a next-generation semiconductor production technology—to be applied to larger substrates. Specifically, it is capable of creating detailed rewiring layers on glass substrates for use in interposers, which are a key component of integrated circuits. In this way, the Coater facilitates the production of high-performance semiconductors.

Toray Engineering has already delivered pilot Coaters to a number of major semiconductor manufacturers to demonstrate its capabilities. Now, the company is preparing to mass-produce the devices, and is targeting orders totaling 3 billion yen by fiscal 2025, and 6 billion yen by fiscal 2030.

In recent years, increased demand for generative AI servers has resulted in a proliferation of hyperscale data centers. As semiconductor performance has improved, the market for high-performance semiconductors has expanded rapidly; at the same time, this technological progress has driven demand for larger-scale and more efficient advanced semiconductor packaging, which is indispensable for the production of advanced semiconductor devices.

Interposers are a key component in advanced semiconductor packaging, and are traditionally made of silicon. However, since interposers are square and silicon wafers are round in shape, cutting square interposers out of 300mm-diameter round silicon wafers inevitably results in waste silicon. Moreover, as semiconductor performance increases, package sizes have been increasing year on year, leading to fears of further decreases in production efficiency.

PLP technologies, which use 600mm-square glass substrates, are seen as a potential solution to the above problems. The larger area of the glass substrate means that larger-scale packages can be produced compared to what is possible with silicon wafers, while its square shape means that the entire substrate can be effectively used to create square interposers without resulting in unused substrate.

Yet the use of PLP technologies to create circuits is not without its own issues: warping of the glass substrate must be prevented, while the wiring materials and photoresist materials must be of a uniform thickness.

To prevent warping, Toray Engineering has developed new technologies for the handling of large glass substrates, drawing on proprietary coating technologies for LCD panels, which are capable of controlling thickness with a high degree of precision. These technologies enable the TRENG-PLP Coater to create high-density rewiring layers on 600mm-square glass substrates.

Hashtag: #toray #TRENG

The issuer is solely responsible for the content of this announcement.

About Toray Engineering

Toray Engineering is a global leader in innovative engineering technologies. Established in 1960, we have been designing and providing plant construction and FA equipment, as well as state-of-the-art manufacturing facilities and equipment such as FPD/semiconductor production equipment, films, and display materials. Under our business brand “TRENG”, we contribute to society by creating new value and realizing solutions to bring about a sustainable society. More information is available at ![]() http://www.toray-eng.com.

http://www.toray-eng.com.

Media OutReach

ECOVACS DEEBOT T90 PRO OMNI with OZMO ROLLER 3.0 and PowerBoost Technology: Simple by Design, Powerful in Action

DEEBOT T90 PRO OMNI and DEEBOT mini 2 Debut at the Singapore IT Show 2026

Marking their first public showcase in Singapore, the DEEBOT T90 PRO OMNI and the DEEBOT mini 2 will officially debut at the Singapore IT Show 2026, taking place from 12 to 15 March 2026. Visitors to the show will be among the first in Singapore to experience ECOVACS’ latest DEEBOT T90 PRO OMNI launch in person, with live demonstrations highlighting its upgraded OZMO ROLLER 3.0 Instant Self-Washing Mopping Technology and PowerBoost Technology with Perpetual Runtime, as well as the refined Nordic-inspired design.

Consumers will also be able to experience the new ultra-compact DEEBOT mini 2, for those seeking a powerful cleaning solution without compromising on space. With a diameter of just 28.6 cm – smaller than a sheet of A4 paper – the DEEBOT mini 2 is designed for small apartments, from compact studios to two-bedroom homes. Despite its size, the DEEBOT mini 2 is equipped with advanced technologies like TrueMapping 2.0 and TrueDetect 3D, to plan cleaning routes and detect different surfaces, providing up to 91% whole-home cleaning coverage. It effortlessly navigates tight corners and hard-to-reach areas, offering 100% edge and corner coverage. Whether it’s under coffee tables, between furniture legs, or in narrow hallways, the DEEBOT mini 2 ensures that no spot is left behind.

The showcase underscores ECOVACS’ commitment to bringing intelligent, hands-free home cleaning innovations closer to local consumers through immersive, hands-on experiences.

Pricing and Availability

The DEEBOT T90 PRO OMNI and DEEBOT mini 2 will be available in Singapore from 8PM on 2 March 2026 via the ECOVACS official webstore, NTUC FairPrice webstore, Shopee, Lazada, and TikTok Shop.

The DEEBOT T90 PRO OMNI will be offered at a pre-sale price of S$1,199 (U.P. $1,899). Purchases made on the official webstore, Fairprice Online, Shopee, Lazada, and Tiktok will include a Tineco iCarpet Spot Cleaner worth S$379, while stocks last.

The DEEBOT mini 2 will be offered at a pre-sale price of S$599 (U.P. $749). Purchases made on the official webstore, Fairprice Online, Shopee, Lazada, and Tiktok will include an accessories pack worth S$48.90, while stocks last.

Hashtag: #ECOVACS

The issuer is solely responsible for the content of this announcement.

About ECOVACS ROBOTICS:

Founded in 2006, ECOVACS ROBOTICS is a global leader in home service robotics with a diverse portfolio of products encompassing robotic vacuum cleaners and robotic window cleaners. With its expansion into robotic lawn mowers, commercial cleaning robots and robotic pool cleaners, ECOVACS solidified its position as a multi-category leader in home service robotics.

Guided by the mission “Robotics for All”, ECOVACS continues to advance technology and enhance the user experience to make life smarter and more stylish for consumers worldwide. With sales subsidiaries in Germany, the United States, Japan, and Singapore, ECOVACS products reach nearly 180 major markets and serve over 38 million households globally.

A testament to this market leadership, ECOVACS ROBOTICS has ranked first in China’s robotic vacuum cleaner market by share for ten consecutive years (2015-2024).

Media OutReach

ECOVACS DEEBOT T90 PRO OMNI with OZMO ROLLER 3.0 and PowerBoost Technology: Simple by Design, Powerful in Action

DEEBOT T90 PRO OMNI and DEEBOT mini 2 Debut at the Singapore IT Show 2026

Marking their first public showcase in Singapore, the DEEBOT T90 PRO OMNI and the DEEBOT mini 2 will officially debut at the Singapore IT Show 2026, taking place from 12 to 15 March 2026. Visitors to the show will be among the first in Singapore to experience ECOVACS’ latest DEEBOT T90 PRO OMNI launch in person, with live demonstrations highlighting its upgraded OZMO ROLLER 3.0 Instant Self-Washing Mopping Technology and PowerBoost Technology with Perpetual Runtime, as well as the refined Nordic-inspired design.

Consumers will also be able to experience the new ultra-compact DEEBOT mini 2, for those seeking a powerful cleaning solution without compromising on space. With a diameter of just 28.6 cm – smaller than a sheet of A4 paper – the DEEBOT mini 2 is designed for small apartments, from compact studios to two-bedroom homes. Despite its size, the DEEBOT mini 2 is equipped with advanced technologies like TrueMapping 2.0 and TrueDetect 3D, to plan cleaning routes and detect different surfaces, providing up to 91% whole-home cleaning coverage. It effortlessly navigates tight corners and hard-to-reach areas, offering 100% edge and corner coverage. Whether it’s under coffee tables, between furniture legs, or in narrow hallways, the DEEBOT mini 2 ensures that no spot is left behind.

The showcase underscores ECOVACS’ commitment to bringing intelligent, hands-free home cleaning innovations closer to local consumers through immersive, hands-on experiences.

Pricing and Availability

The DEEBOT T90 PRO OMNI and DEEBOT mini 2 will be available in Singapore from 8PM on 2 March 2026 via the ECOVACS official webstore, NTUC FairPrice webstore, Shopee, Lazada, and TikTok Shop.

The DEEBOT T90 PRO OMNI will be offered at a pre-sale price of S$1,199 (U.P. $1,899). Purchases made on the official webstore, Fairprice Online, Shopee, Lazada, and Tiktok will include a Tineco iCarpet Spot Cleaner worth S$379, while stocks last.

The DEEBOT mini 2 will be offered at a pre-sale price of S$599 (U.P. $749). Purchases made on the official webstore, Fairprice Online, Shopee, Lazada, and Tiktok will include an accessories pack worth S$48.90, while stocks last.

Hashtag: #ECOVACS

The issuer is solely responsible for the content of this announcement.

About ECOVACS ROBOTICS:

Founded in 2006, ECOVACS ROBOTICS is a global leader in home service robotics with a diverse portfolio of products encompassing robotic vacuum cleaners and robotic window cleaners. With its expansion into robotic lawn mowers, commercial cleaning robots and robotic pool cleaners, ECOVACS solidified its position as a multi-category leader in home service robotics.

Guided by the mission “Robotics for All”, ECOVACS continues to advance technology and enhance the user experience to make life smarter and more stylish for consumers worldwide. With sales subsidiaries in Germany, the United States, Japan, and Singapore, ECOVACS products reach nearly 180 major markets and serve over 38 million households globally.

A testament to this market leadership, ECOVACS ROBOTICS has ranked first in China’s robotic vacuum cleaner market by share for ten consecutive years (2015-2024).

Media OutReach

ECOVACS DEEBOT T90 PRO OMNI with OZMO ROLLER 3.0 and PowerBoost Technology: Simple by Design, Powerful in Action

DEEBOT T90 PRO OMNI and DEEBOT mini 2 Debut at the Singapore IT Show 2026

Marking their first public showcase in Singapore, the DEEBOT T90 PRO OMNI and the DEEBOT mini 2 will officially debut at the Singapore IT Show 2026, taking place from 12 to 15 March 2026. Visitors to the show will be among the first in Singapore to experience ECOVACS’ latest DEEBOT T90 PRO OMNI launch in person, with live demonstrations highlighting its upgraded OZMO ROLLER 3.0 Instant Self-Washing Mopping Technology and PowerBoost Technology with Perpetual Runtime, as well as the refined Nordic-inspired design.

Consumers will also be able to experience the new ultra-compact DEEBOT mini 2, for those seeking a powerful cleaning solution without compromising on space. With a diameter of just 28.6 cm – smaller than a sheet of A4 paper – the DEEBOT mini 2 is designed for small apartments, from compact studios to two-bedroom homes. Despite its size, the DEEBOT mini 2 is equipped with advanced technologies like TrueMapping 2.0 and TrueDetect 3D, to plan cleaning routes and detect different surfaces, providing up to 91% whole-home cleaning coverage. It effortlessly navigates tight corners and hard-to-reach areas, offering 100% edge and corner coverage. Whether it’s under coffee tables, between furniture legs, or in narrow hallways, the DEEBOT mini 2 ensures that no spot is left behind.

The showcase underscores ECOVACS’ commitment to bringing intelligent, hands-free home cleaning innovations closer to local consumers through immersive, hands-on experiences.

Pricing and Availability

The DEEBOT T90 PRO OMNI and DEEBOT mini 2 will be available in Singapore from 8PM on 2 March 2026 via the ECOVACS official webstore, NTUC FairPrice webstore, Shopee, Lazada, and TikTok Shop.

The DEEBOT T90 PRO OMNI will be offered at a pre-sale price of S$1,199 (U.P. $1,899). Purchases made on the official webstore, Fairprice Online, Shopee, Lazada, and Tiktok will include a Tineco iCarpet Spot Cleaner worth S$379, while stocks last.

The DEEBOT mini 2 will be offered at a pre-sale price of S$599 (U.P. $749). Purchases made on the official webstore, Fairprice Online, Shopee, Lazada, and Tiktok will include an accessories pack worth S$48.90, while stocks last.

Hashtag: #ECOVACS

The issuer is solely responsible for the content of this announcement.

About ECOVACS ROBOTICS:

Founded in 2006, ECOVACS ROBOTICS is a global leader in home service robotics with a diverse portfolio of products encompassing robotic vacuum cleaners and robotic window cleaners. With its expansion into robotic lawn mowers, commercial cleaning robots and robotic pool cleaners, ECOVACS solidified its position as a multi-category leader in home service robotics.

Guided by the mission “Robotics for All”, ECOVACS continues to advance technology and enhance the user experience to make life smarter and more stylish for consumers worldwide. With sales subsidiaries in Germany, the United States, Japan, and Singapore, ECOVACS products reach nearly 180 major markets and serve over 38 million households globally.

A testament to this market leadership, ECOVACS ROBOTICS has ranked first in China’s robotic vacuum cleaner market by share for ten consecutive years (2015-2024).

-

Feature/OPED6 years ago

Feature/OPED6 years agoDavos was Different this year

-

Travel/Tourism10 years ago

Lagos Seals Western Lodge Hotel In Ikorodu

-

Showbiz3 years ago

Showbiz3 years agoEstranged Lover Releases Videos of Empress Njamah Bathing

-

Banking8 years ago

Banking8 years agoSort Codes of GTBank Branches in Nigeria

-

Economy3 years ago

Economy3 years agoSubsidy Removal: CNG at N130 Per Litre Cheaper Than Petrol—IPMAN

-

Banking3 years ago

Banking3 years agoSort Codes of UBA Branches in Nigeria

-

Banking3 years ago

Banking3 years agoFirst Bank Announces Planned Downtime

-

Sports3 years ago

Sports3 years agoHighest Paid Nigerian Footballer – How Much Do Nigerian Footballers Earn